In today’s rapidly developing industrial sector, high-frequency welded pipe production lines play a crucial role. Welded pipe equipment provides high-quality straight seam welded pipe products for various industries. This article will delve into the working principle, application areas, and importance of welded pipe production lines to modern industry.

Working Principle of High-Frequency Welded Pipe Production Lines

High-frequency welded pipe production lines are highly automated and efficient continuous production equipment.

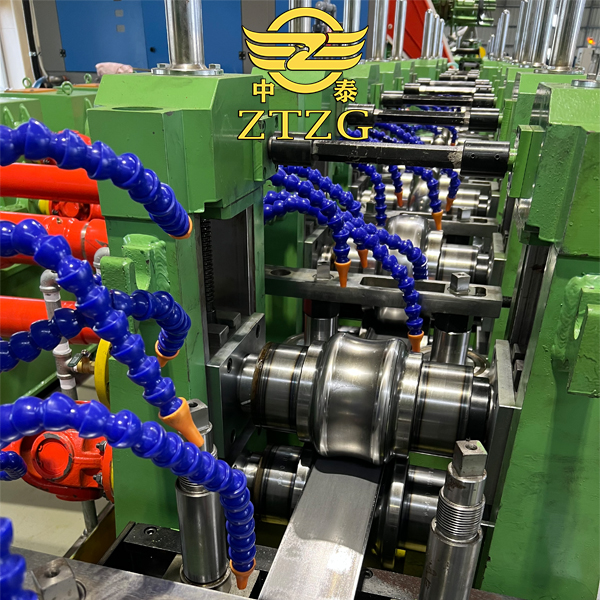

They use high-frequency induction welding technology to weld metal strips into tubular structures. This technology utilizes the magnetic field generated by high-frequency current to generate heat at the contact point of the metal strip, thereby achieving welding. Compared with traditional welding methods, high-frequency induction welding has advantages such as high speed, low energy consumption, and good weld quality.

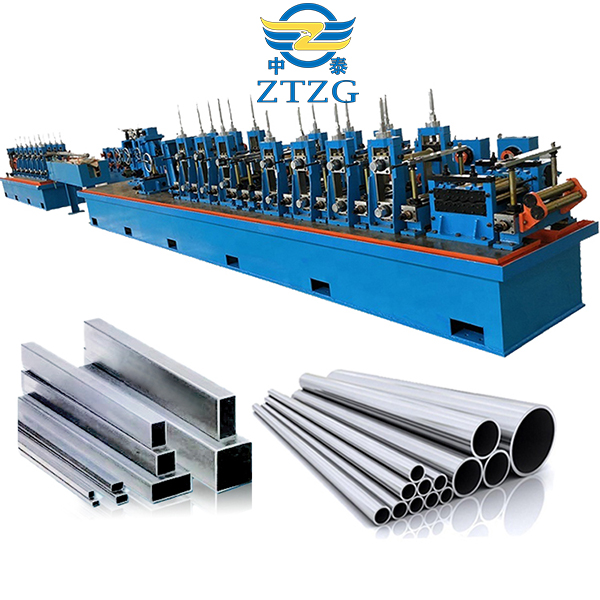

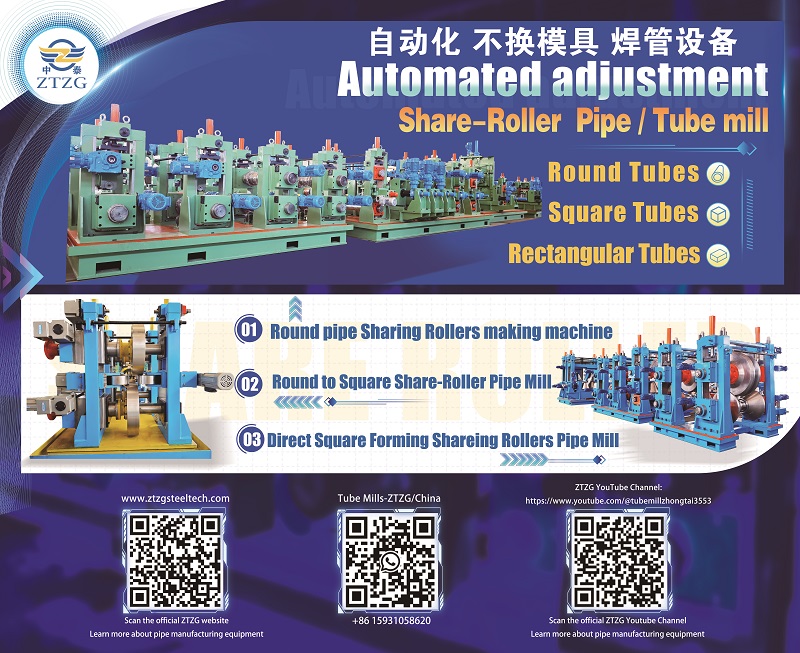

High-frequency welded pipe production lines can not only produce traditional round pipes but also square, rectangular, and other irregularly shaped pipes according to demand. This flexibility allows it to meet the special requirements of different industries for pipe shapes.

Application Areas of High-Frequency Welded Pipe Production Lines

Due to their superior performance and wide applicability, high-frequency welded pipe production lines are widely used in multiple fields:

1. Construction Industry: As an important component of building structures, such as scaffolding and pipes.

2. Precision Tube Industry: Used to manufacture pipes requiring high-precision dimensions and surface finishes.

3. Automotive Industry: Used to manufacture automotive exhaust pipes, shock absorbers, and other components.

4. Fence Manufacturing: Produces pipes for fences, railings, etc.

5. Heat Exchanger Industry: Used to manufacture heat exchanger tubes in heat exchangers.

6. Furniture Industry: Used for furniture frame structures and support components.

7. Pressure Pipe Industry: Used to manufacture piping systems that withstand high pressure.

Importance of High-Frequency Welded Pipe Production Lines

The high efficiency and flexibility of high-frequency welded pipe production lines make them an indispensable part of modern industry. They not only improve production efficiency and reduce production costs but also enhance the competitiveness of industrial products through high-quality output. Furthermore, with continuous technological advancements, high-frequency welded pipe production lines are constantly being innovated and improved to adapt to market changes and demands.

With technological advancements and evolving market demands, high-frequency welded pipe production lines are evolving towards greater automation and intelligence. ZTZG has independently developed and manufactured automated, mold-free welding pipe equipment, capable of producing steel pipes of different specifications without changing rollers and allowing for online adjustments to production specifications. In the future, we may see more intelligent control systems and robotics integrated into welded pipe production lines to further improve production efficiency and product quality.

When selecting a high-frequency welded pipe production line manufacturer, several key factors need to be considered, including technical strength, production capacity, product quality, service support, and market reputation. ZTZG focuses on the research, development, production, and manufacturing of high-frequency welded pipe production lines, possessing over 20 years of industry experience and strong production capabilities, earning the recognition of numerous pipe manufacturing clients.

Post time: Jan-07-2026