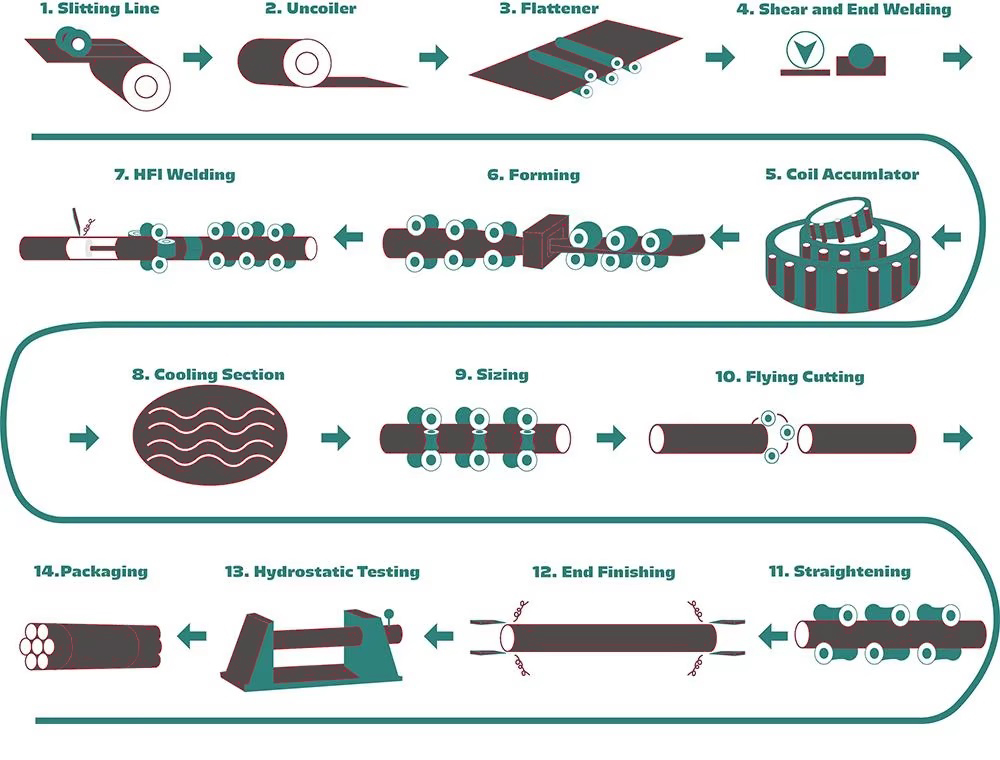

Welded pipe equipment is a highly efficient automated production line that processes steel coils into finished pipes. The core production stages include:

1. Uncoiling & Leveling :The steel coil is unwound through an uncoiler and leveled by a straightening machine to eliminate curling stress and ensure flatness.

2. Forming & Welding:The steel strip enters a continuous forming unit where multiple sets of rollers gradually shape it into round/square/rectangular tubing. High-frequency induction welding then fuses the seam to create a sealed pipe body.

3.Weld Seam Treatment:The welded joint undergoes deburring (via planing or grinding) and quality inspection using eddy current or ultrasonic testing systems.

4.Sizing & Cooling:Pipes pass through a sizing mill for precise diameter calibration, followed by a water cooling system for shape setting.

5.Cutting & Bundling:A flying saw cuts pipes to specified lengths, with finished products straightened and bundled for storage.

Customizable ERW pipe mill produces pipes in various specifications and materials for construction, transportation, automotive, and oil/gas pipeline applications.

Post time: Aug-15-2025