Fully automated Share-Roller ERW pipe mill represents a significant technological advancement in the field of ERW pipe production. Compared to traditional ERW pipe mill, it offers notable advantages in production efficiency, flexibility, and cost control.

1. Production Efficiency

Traditional ERW Pipe Mill requires frequent mold changes to accommodate different pipe diameters or wall thicknesses, leading to increased downtime and lower production efficiency. In contrast, fully automated Share-Roller ERW Pipe Mill utilizes advanced flexible forming technology, enabling rapid adjustments through digital parameter settings, significantly reducing downtime and boosting output.

2. Process Flexibility

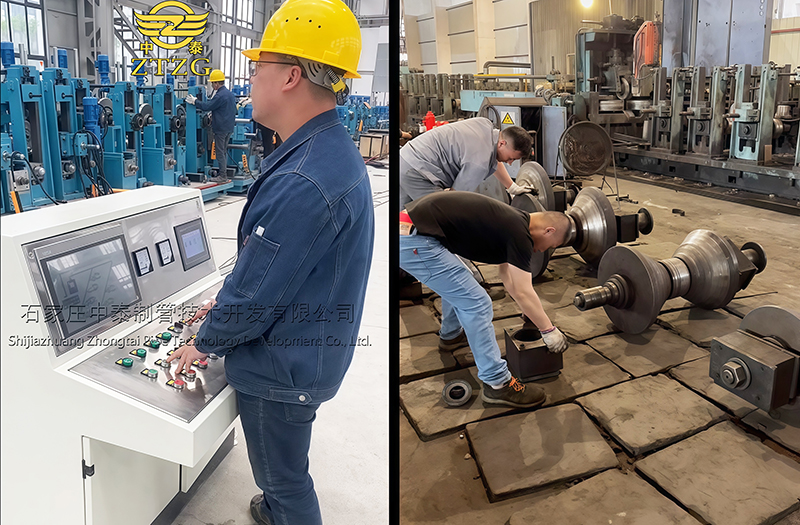

Traditional ERW Pipe Mill relies on fixed Roller, limiting production specifications and complicating adjustments. Fully automated systems employ servo-driven mechanisms and intelligent control systems, allowing the production of various pipe specifications without mold changes. This adaptability meets the demands of small-batch, multi-variety orders, greatly enhancing market competitiveness.

3. Cost and Maintenance

Traditional ERW Pipe Mill incurs high Roller costs, and Roller replacement and maintenance are time- and labor-intensive. Fully automated ERW Pipe Mill reduces dependence on Rollers, lowering spare parts expenses. Additionally, its intelligent monitoring system enables real-time status detection, reducing failure rates and extending service life.

4. Product Quality

Fully automated ERW Pipe Mill employs high-precision closed-loop control to ensure stable forming and welding, resulting in superior dimensional consistency compared to traditional methods. This makes it particularly suitable for industries with stringent precision requirements.

Conclusion

With its advantages in efficiency, flexibility, and cost-effectiveness, fully automated Share-Roller ERW Pipe Mill is gradually replacing traditional systems, becoming a key driver of innovation in ERW pipe manufacturing.

ZTZG independently developed, designed and produced round pipe, round to square, direct to square without changing roller process ERW pipe mill.

Provide professional ERW pipe mill production lines for downstream steel pipe, steel structure and cold-formed steel manufacturers.

Post time: Jul-15-2025