The development of steel pipe production technology began with the rise of the bicycle manufacturing industry. The early 19th-century development of oil, the construction of ships, boilers, and aircraft during the two World Wars, the post-World War II construction of thermal power boilers, the development of the chemical industry, and the drilling and transportation of oil and natural gas all powerfully propelled the development of the steel pipe industry in terms of variety, output, and quality.

Steel pipes are classified into two types according to their production methods: seamless steel pipes and welded steel pipes. This article will mainly introduce welded steel pipes.

Welded steel pipes, also known as seamless steel pipes, are produced by bending billets (steel plates and strips) into the required cross-sectional shape and size using various forming methods, and then welding the seams together using different welding methods.

Straight seam high-frequency welded pipes (ERW) are produced by forming hot-rolled coils using a forming machine, then using the skin effect and proximity effect of high-frequency current to heat and melt the edges of the billet, and finally pressure welding them under the action of extrusion rollers.

Steel pipe manufacturing process:

Scrolling Up→ Uncoiling → Shear and Welding→ Accumulator→ Forming→ HF induction Welding→ External Burr Removing→ Cooling → Sizing→ Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse

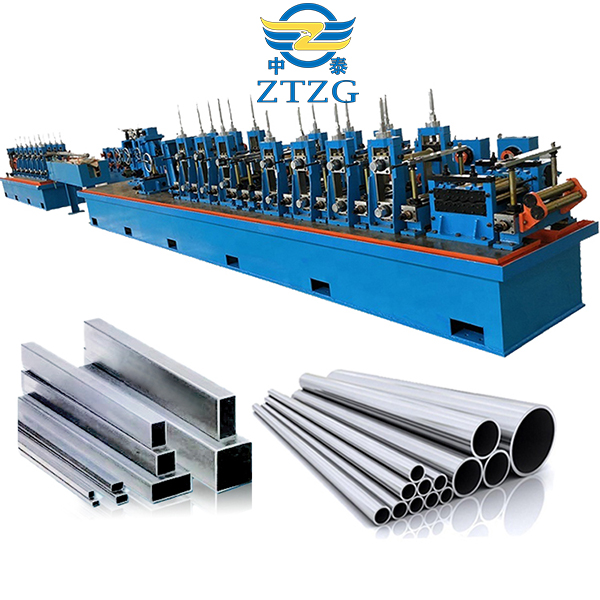

| ZTZG——China Professional Manufacturer Of Pipe/Tube Mill |

| ZTZG Welded Pipe mill was established in 2000, and it has been 25 years. The main products are round pipe mill, square and rectangular pipe mill, special-shaped pipe mill, and open cold-bent steel mill. |

| More than 25 years of independent research and development and manufacturing experience. Passed ISO9001 quality system certification and participated in the preparation of a number of industry standards.ZTZG support customization according to international standards in each region, and provide regular technical information and technical training support.There is strict quality control in raw materials, processing accuracy, heat treatment, assembly accuracy, standard parts, etc. The pass rate of equipment delivery is 100%. |

| We uphold a consistent level of professionalism, top quality, credibility and repair for China Pipe Making Machine and Steel Pipe Making Machine, our tube mill durable modeling and promoting effectively all over the world. |

Post time: Nov-18-2025