Amidst increasingly fierce market competition, a large steel pipe mill faced a production efficiency bottleneck. To address this challenge, the mill decisively invested in a comprehensive and in-depth upgrade of its outdated pipe welding equipment.

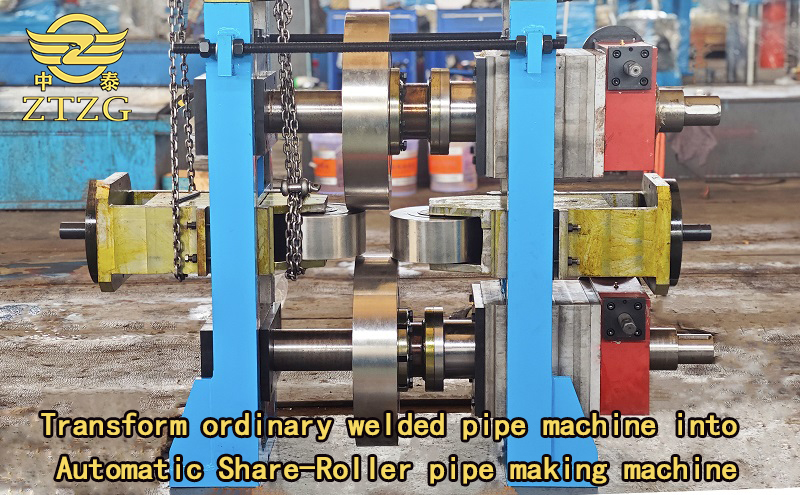

The upgrade focused on the introduction of a Zhongtai automated, die-free high-frequency straight seam pipe welding line. This line integrates multiple cutting-edge technologies, including a fully automatic control system, temperature control system, and digital parameter adjustment. Compared to traditional pipe welding equipment, Zhongtai’s new equipment achieved a quantum leap in welding speed, precision, and stability.

The upgraded pipe welding line significantly increased welding speed, reaching up to 150 meters per minute—twice the speed of the original equipment.

Secondly, the fully automatic control system reduced manual intervention, significantly lowered defective rates, and ensured consistent product quality.

Additionally, the digital management system enabled real-time monitoring of production data, facilitating precise adjustments and fault prediction by engineers.

Through this technological innovation, the mill’s overall production efficiency increased by over 30%, shortened delivery cycles by 20%, and effectively reduced operating costs. This not only consolidates its leading position in the industry, but also lays a solid foundation for future market expansion and taking on more high-demand orders.

Welcome to contact us to get detailed information about welding pipe equipment

Post time: Sep-18-2025