Choosing the right welded pipe production machine manufacturer is crucial for a pipe manufacturer’s production efficiency and product quality.

I. Clarifying Your Needs and Positioning

1. Type and Specifications of Welded Pipe Equipment

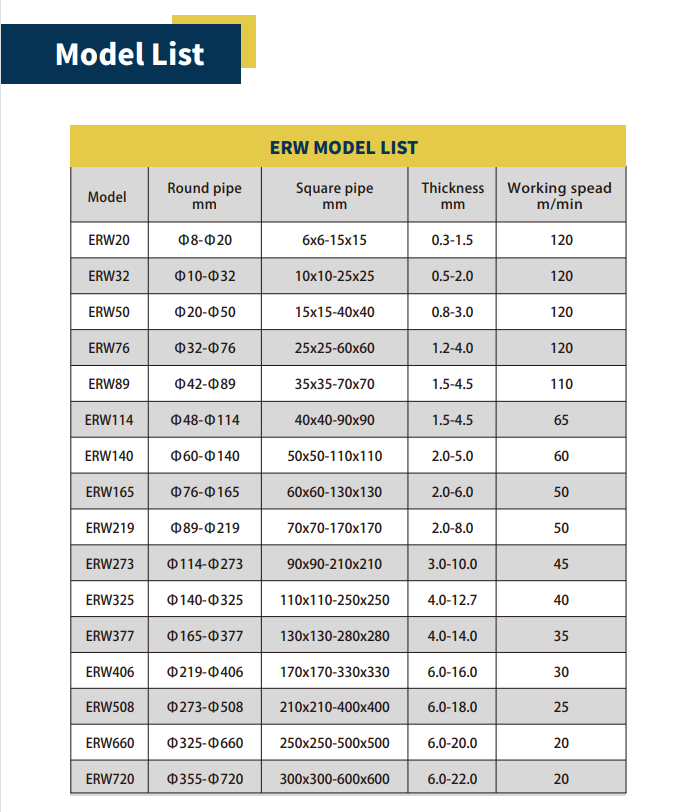

◆Determine the material of the welded pipe to be produced (carbon steel, stainless steel, alloy steel, etc.), pipe diameter range, wall thickness, production speed (meters/minute), and process (straight seam high-frequency welding, spiral welding, precision welding, etc.).

◆Special requirements: such as whether online heat treatment, internal weld scar removal, laser welding, etc., are needed.

2. Capacity and Budget of Welded Pipe Production Line

◆Plan the annual production target and match it with the actual capacity of the equipment (e.g., 20-50 tons/hour).

◆Set a reasonable budget, taking into account equipment costs, installation, training, and long-term maintenance costs.

3. Future Expandability of the Pipe Manufacturing Machine

◆Is it necessary to reserve space for upgrades (e.g., diameter expansion, speed increase, automation transformation)?

II. Assessing the Overall Strength of Welded Pipe Equipment Manufacturers

1. Technology and R&D Capabilities

● Core Technology: Examine the key technologies of their welded pipe equipment (e.g., forming process, control system stability).

● Case Studies and Patents: Review successful cases (especially similar products), number of patents, and background of the technical team.

● Customization Capabilities: Can they adjust the design of welded pipe production lines according to needs and provide non-standard solutions?

2. Manufacturing Quality and Standards of Welded Pipe Production Lines

● Production Process: Examine the processing precision of the pipe-making machine factory (e.g., frame rigidity and processing technology) and assembly quality.

● Source of Core Components: Do the key components of the pipe-making machine (e.g., PLC, bearings, laser heads) use internationally renowned brands (e.g., Siemens, ABB)?

● Testing Equipment: Is the factory equipped with a complete testing system (e.g., online eddy current testing, ultrasonic thickness measurement)?

3. Industry Reputation and History

● Establishment Time and Customer Base: Prioritize welded pipe equipment manufacturers with a long history in the industry and having served multiple well-known companies.

● On-site Visit: Visit the welded pipe production line manufacturing plant and existing customer welded pipe production lines to observe the operating status of the welded pipe equipment.

● Industry Evaluation: Gain reputation through industry associations, exhibitions (such as the China International Pipe & Steel Exhibition), or peer recommendations.

III. Key Equipment Performance Comparison

1. Efficiency and Energy Consumption of Welded Pipe Production Lines

▲ Compare the actual output rate, yield rate (e.g., ≥98%), and unit energy consumption (electricity cost as a percentage of total cost) of different brands of equipment.

2. Automation and Intelligence of Pipe Making Machines

▲ Whether equipped with automatic deviation correction, online quality monitoring, and MES production management system to reduce manual intervention.

3. Stability and Lifespan of Welded Pipe Equipment

▲ Check the design life of key components (e.g., wear-resistant treatment of rolls) and mean time between failures (MTBF).

Post time: Feb-02-2026