**Key Factors to Consider When Selecting High-Frequency Welded Pipe Equipment**

To ensure production efficiency and quality, the following key factors should be comprehensively evaluated when choosing high-frequency welded pipe equipment:

1. Production Requirements Analysis

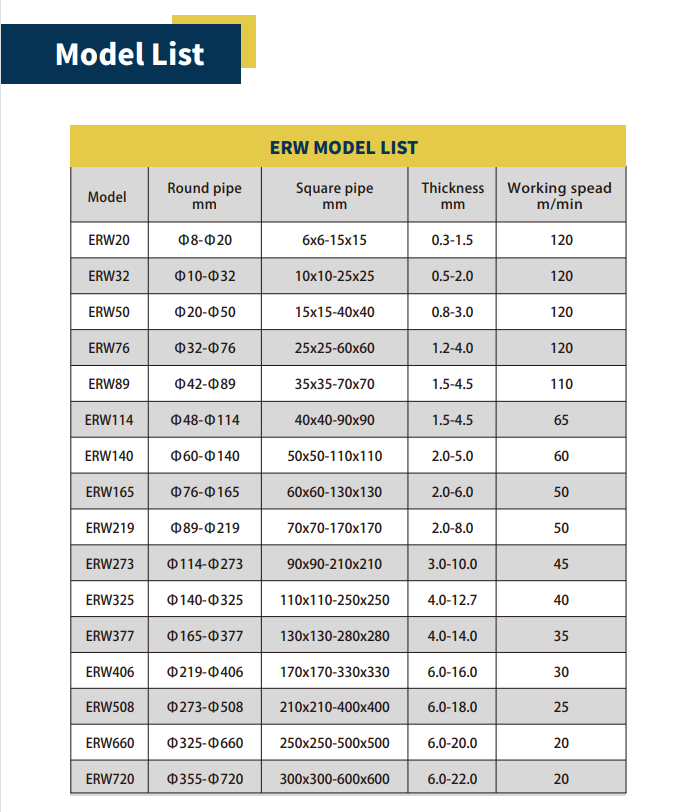

- **Pipe Specifications**: Determine the required diameter (e.g., Φ20mm-Φ200mm), wall thickness, and material (carbon steel, stainless steel, etc.).

- **Production Capacity**: Select the equipment speed (e.g., 20-120 meters/minute) based on daily/monthly output requirements.

2. Core Performance of Welded Pipe Equipment

- **Welding Frequency**: High frequency (100-400kHz) is suitable for thin-walled pipes, while medium frequency (1-10kHz) is ideal for thick-walled pipes.

- **Automation Level**: Fully automated production lines (e.g., automatic feeding and cutting) can significantly reduce labor costs.

3. Energy Efficiency and Maintenance

- Prioritize energy-saving high-frequency generators to minimize long-term operational costs.

- Ensure the equipment is easy to maintain (e.g., quick mold replacement design or mold-free processes).

4. Supplier Services

- Evaluate the manufacturer’s overall capabilities, technical support, and after-sales response time to guarantee stable operation of the welded pipe equipment.

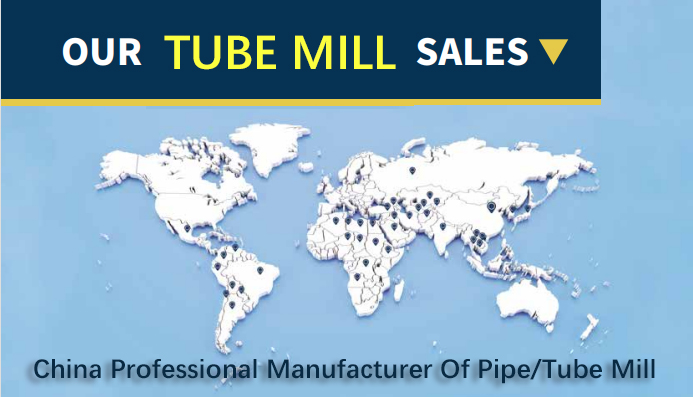

ZTZG Welded Pipe mill was established in 2000, and it has been 25 years.

Original Factory for Welded Tube & Pipe Machines.

Our Welded Pipe mill Supplied Across the Nation Exporting to Countries Worldwide.

Post time: Jun-28-2025