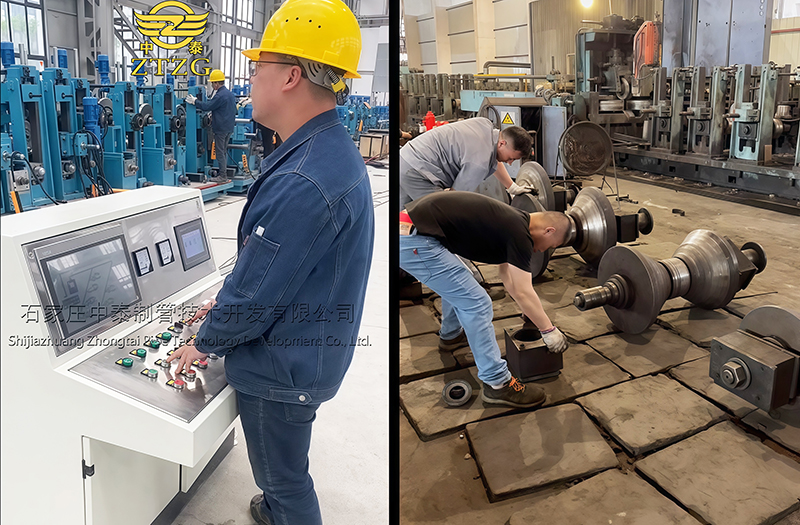

Amidst the deafening roar of the welded pipe workshop, a production worker sighs: “It’s roller replacement again”—this seemingly simple process brings the entire production line to a standstill. The heavy rollers require multiple workers working together, taking half a day to complete the replacement and adjustment. And this downtime repeats itself whenever production specifications are changed.

The Growing Pains of the Pipe Making Machine Industry: When Traditional welded pipe production line Meets the Challenges of the Times

With intensifying market competition and increasingly diversified customer demands, small-batch, multi-variety orders have become the norm.

Traditional welded pipe production line faces severe challenges: frequent roller replacements lead to low production efficiency, human error affects product consistency, and high labor costs squeeze profit margins.

Most critically, these outdated machines cannot adapt to rapidly changing market demands.

This is not only a loss of time, but also a loss of competitiveness. The market won’t wait, and customers won’t understand.

The Intelligent Upgrade of Pipe Making Machines: Automated, Share-Roller Welded Pipe Equipment

ZTZG independently researched, designed, and modified the most challenging mechanical structure. Upgrading key components of welded pipe production equipment and adding servo drives and linear guide systems allows the same set of molds to adapt to different pipe specifications within a specified parameter range, eliminating the need for physical replacements. This significantly improves positioning accuracy and response speed. Welded pipe production line operators no longer rely on traditional experience but instead use data visualization to precisely monitor production status.

The benefits of intelligent pipe-making machines are evident: Data witnesses the evolution and transformation of welded pipe production lines.

After implementing the new intelligent welded pipe production line, customer workshops have seen reduced average changeover time, increased equipment utilization, and higher first-pass yields, resulting in significantly improved efficiency.

The head of the quality inspection department stated, “What surprised me most was not the efficiency improvement, but the stability of product quality.” “Previously, there were always slight differences between different batches of products; now they are almost completely consistent.”

ZTZG Automated Share-Roller Welded Pipe Production Line:

Online specification adjustment, no more roller replacements

Time-saving, labor-saving, and highly efficient

Less equipment wear

Flexible order response, seizing market opportunities

Post time: Jan-22-2026