Square tubes are widely used in construction structures, automotive manufacturing, furniture and appliances, fitness equipment, and other fields, as well as in high-strength applications such as heavy machinery.

With the expansion of market demand, the production processes for high-frequency straight-seam square tubes are continuously advancing.

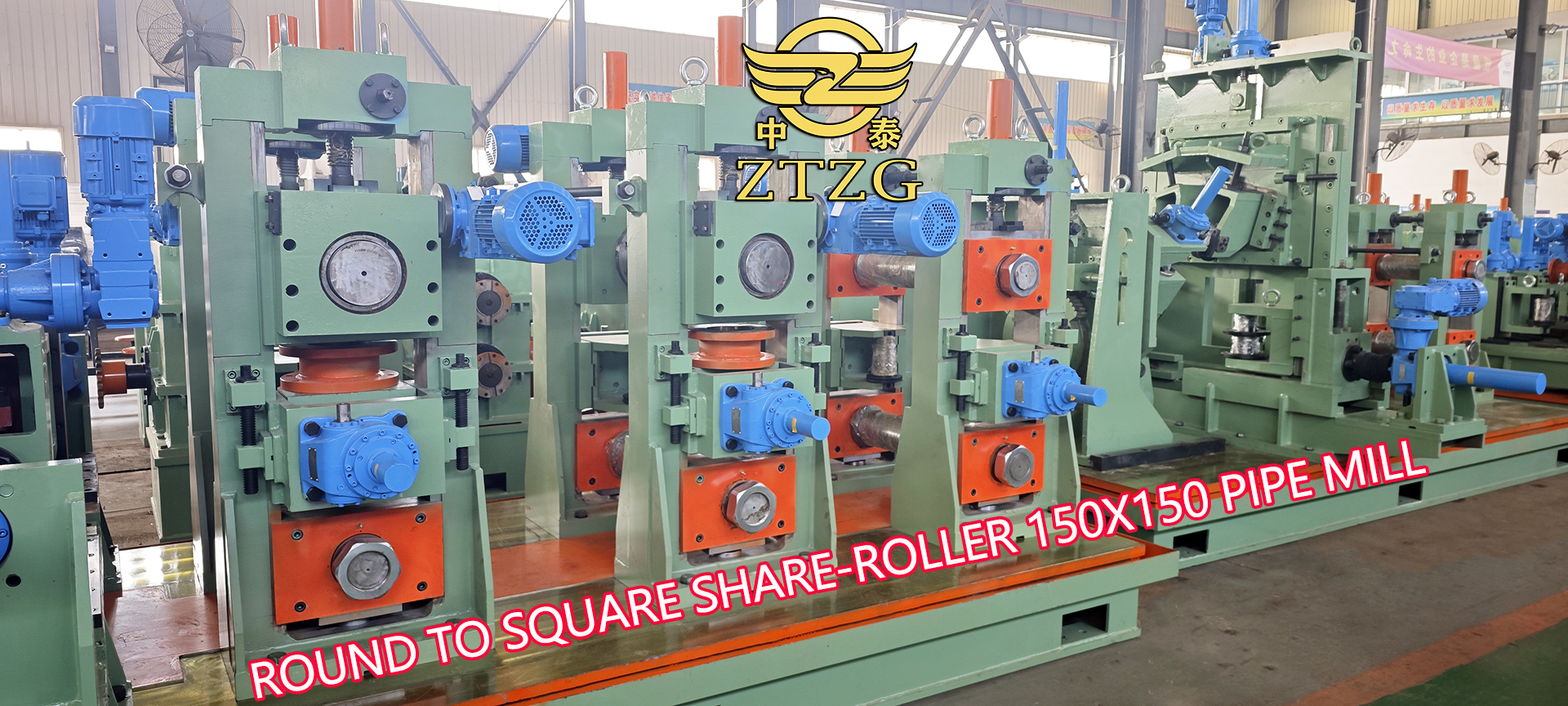

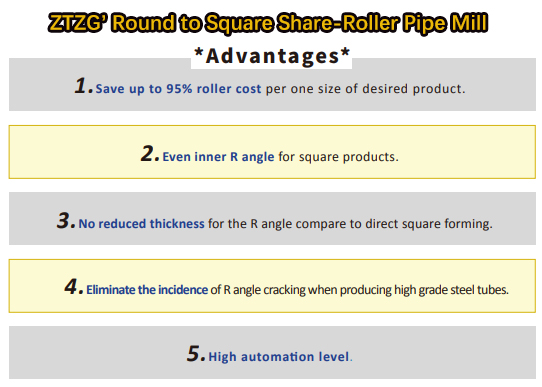

ZTZG‘s Round-to-Square Share-Roller pipe mill can produce both round tubes and square tubes.

The steel strip forming section before welding does not require mold changes, and the sizing section adopts the round-to-square without mold change process.

With its independently developed special structure, it achieves the goal of shared rollers, significantly reducing roller adjustment time and improving production efficiency!

Moreover, the round-to-square without mold change pipe welding production line minimizes scratches on steel tubes.

The formed tubes maintain uniform wall thickness for both round and square shapes, with a more perfect tube profile, making it highly suitable for small-diameter, thick-walled products!

ZTZG‘s DFT Share-roller Pipe Mill is a fully automated production line that requires no roller changes.

It can produce square and rectangular tubes of different specifications without replacing rollers, enabling full-flow online adjustments.

Mechanical adjustments ensure higher precision, and the finished tubes have a more regular shape.

Pipe manufacturers producing multi-specification square and rectangular tubes should definitely check it out!

Post time: Jun-24-2025