As the lifeblood of industry, pipe-making machine technology upgrades continuously drive innovation in manufacturing.

Let’s uncover the core technologies behind high-precision welded pipe production lines:

【Breakthrough Production Line in the Welded Pipe Equipment Industry】

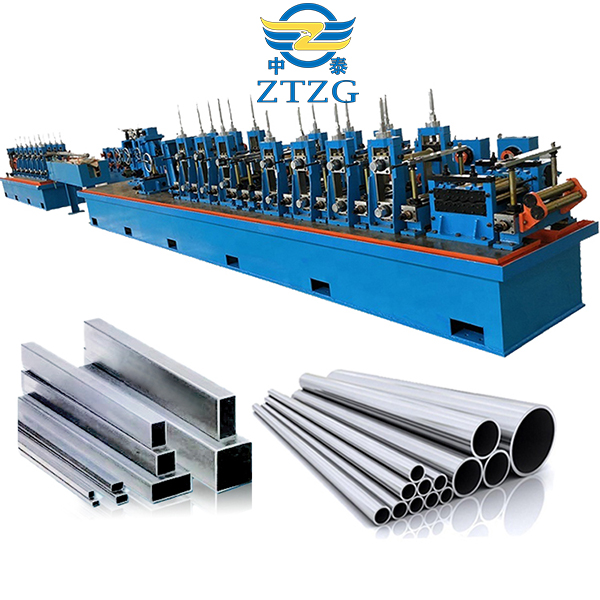

ZTZG’s fully automated, share-roller welded pipe production line enables the production of steel pipes of different specifications, with online diameter switching throughout the entire process, allowing for customized production and covering all customer requirements.

【Precision Control Welded Pipe Production Line】

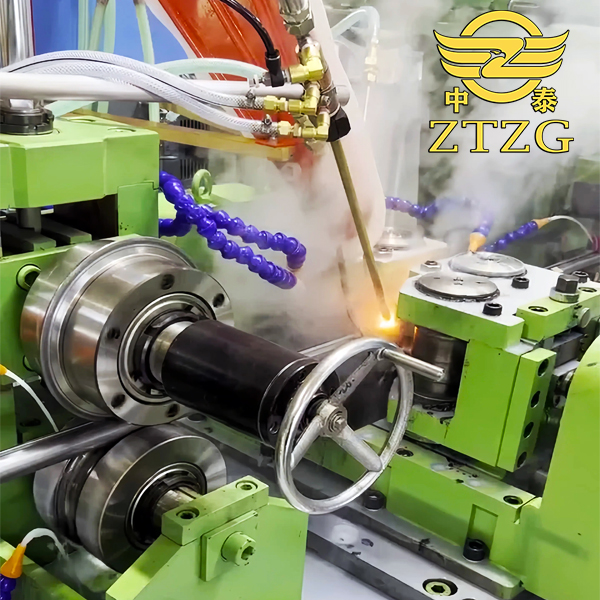

ZTZG’s share-roller pipe-making machine uses motor adjustment in the forming and sizing sections, automatically adjusting distances and controlling each motor for precise control and positioning. The welding section employs an advanced temperature control system, resulting in higher precision and more regular finished pipe shapes through mechanized adjustment.

【Intelligent Manufacturing Customization】

Targeting the production needs of small to medium-sized, medium to large-sized, high-speed, and high-precision welded pipes, different welding pipe equipment processes are available, all achieving improvements such as reduced mold investment, high production efficiency, reduced equipment wear, and lower labor intensity.

【Future Trends Preview】

ZTZG’s share-roller pipe-making machine has received certification from the welded pipe equipment industry association and high recognition from numerous pipe-making customers. The share-roller welded pipe production line will rewrite the traditional, inefficient welded pipe equipment landscape.

Post time: Jan-19-2026