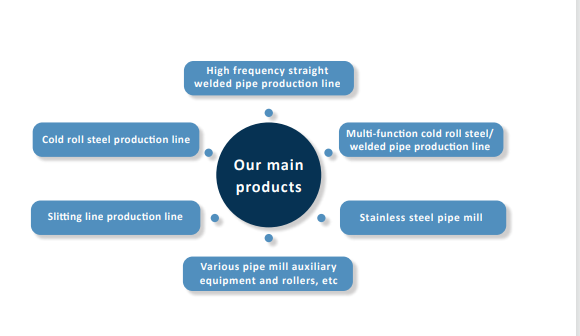

ERW pipe mill can be categorized into the following types based on production processes, applications, and structural characteristics:

By Forming Process

Longitudinal Seam ERW pipe mill: Used for producing straight-seam welded steel pipes, such as high-frequency welded pipe units and submerged arc welded pipe units.

Spiral Welded Pipe machine: Used for manufacturing spiral seam steel pipes, suitable for large-diameter pipeline production.

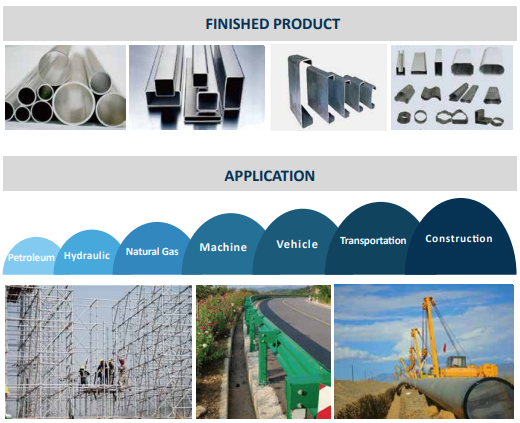

By Pipe Type (Cross-Section Shape)

Round Pipe machine, Square/Rectangular Pipe machine, Special-Shaped Pipe machine, Open Cold-Formed Steel machine.

By Welding Method

High-Frequency ERW pipe mill: Utilizes high-frequency current for heating and welding, suitable for thin-walled pipe production.

Arc Welded Pipe Equipment: Includes submerged arc welding (SAW), gas-shielded welding (MIG/MAG), etc., suitable for thick-walled pipes and high-strength steel welding.

Laser Welded Pipe Equipment: High-precision welding for manufacturing precision pipes.

By Application

General ERW pipe mill: Produces pipes for construction and structural use.

Specialized ERW pipe mill: Such as equipment for oil casing pipes, boiler pipes, and other specialized applications.

Precision ERW tube mill: For applications like automotive drive shafts and furniture pipes, requiring high precision and control over pipe roundness and surface smoothness.

Galvanized ERW pipe mill: Used for rust-proof applications like construction and electrical conduits, adding hot-dip galvanizing or electro-galvanizing processes to welded pipes.

The selection of ERW pipe mill should align with production needs, as it involves non-standard, customized solutions. If you have any further questions, feel free to contact us for consultation~

Post time: Jul-22-2025