When purchasing welded pipe mill, manufacturers often emphasize production capacity and price, but the following critical issues are easily overlooked:

1. Durability of core components (e.g., forming rolls, high-frequency welders)?

Low-cost welded pipe machine may use inferior steel, leading to rapid roll wear and high replacement costs.

2. What are the energy consumption and maintenance costs?

Some welded pipe production line requires frequent replacement of wear-prone parts (e.g., guide plates, welding coils), resulting in long-term costs far exceeding the budget.

3. How responsive is technical support and after-sales service?

Some welded pipe mill manufacturers have slow after-sales responses, with repairs taking weeks, severely impacting production schedules.

4. Does it support customized production?

If producing special-shaped pipes or materials (e.g., stainless steel), verify whether the welded pipe equipment can accommodate the required process adjustments.

Visit the manufacturer’s customer sites for on-site inspections to avoid selection risks due to information asymmetry.

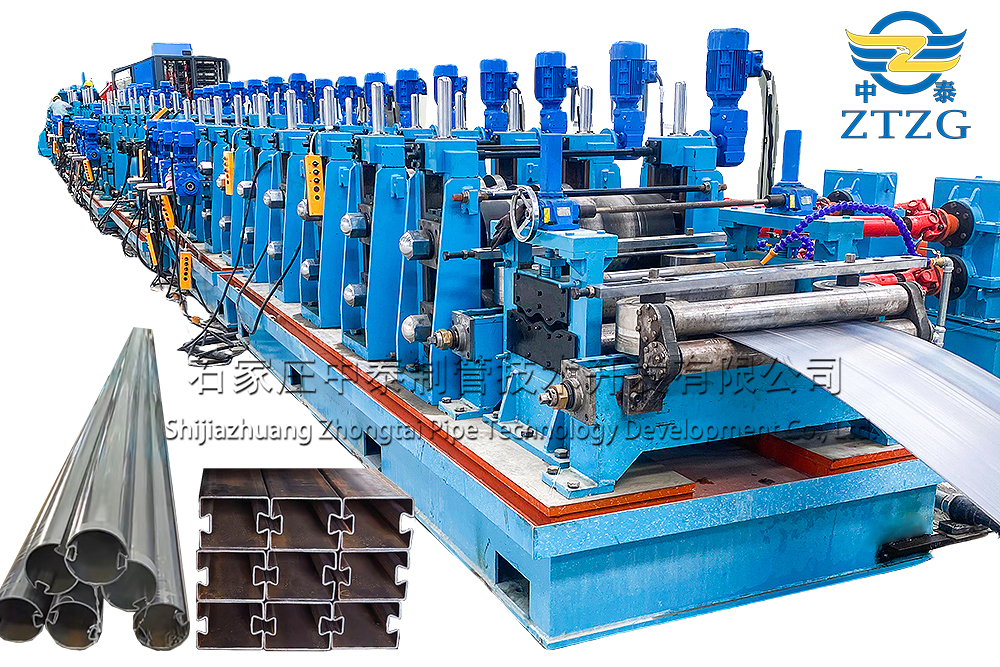

ZTZG’ pipe mill, established in 2000, has 25 years of industry experience.

Our main products include:

- Round pipe production machine

- Square & rectangular pipe production line

- Special-shaped pipe production equipment

- Open-section cold-formed steel production equipment

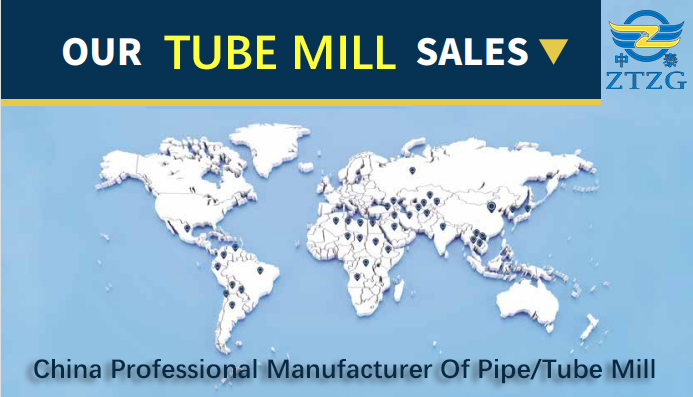

ZTZG’s ERW pipe machinery has been exported worldwide, serving markets in Russia, Southeast Asia, Europe, South America, Japan, Turkey, and many other countries and regions. We support customized solutions to meet international standards in different regions.

Post time: Aug-19-2025