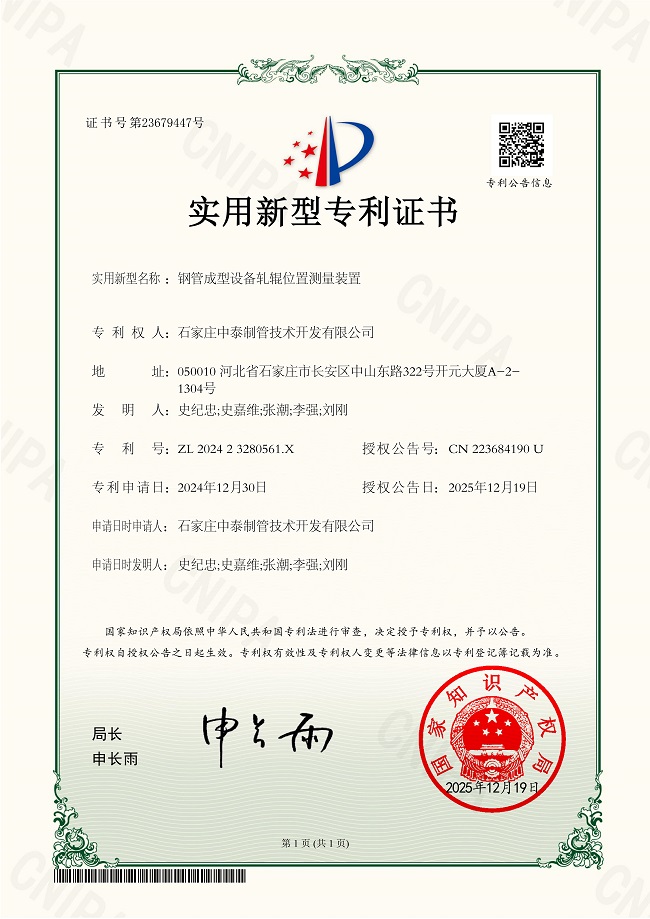

Recently, ZTZG’s patent application for “Roll Position Measuring Device for Steel Pipe Forming Equipment” was officially authorized by the State Intellectual Property Office, marking another advancement for ZTZG in technological innovation and independent intellectual property rights.

The working principle of steel pipe forming equipment relies on the extrusion of two vertically spaced rollers in a fixed frame to plastically deform the steel strip, achieving the desired product shape. Therefore, the positional changes and positioning of each roller directly determine the forming quality of the product.

The roll position measuring device for steel pipe forming equipment has a fixing mechanism at one end that can be fixed to the steel pipe forming equipment, and the other end that can extend horizontally outward. The adjusting measuring mechanism can be adjusted to horizontal and vertical measurement states via a sliding measuring part.

In the horizontal measurement state, it can measure the horizontal displacement of the rollers, and in the vertical measurement state, it can measure the distance between the two rollers.

ZTZG’s innovative advantages: Compared with existing technologies, it solves the problem of high workload and time-consuming adjustment when setting up existing position measuring devices. The adjustment and measurement work is less labor-intensive, saving time and effort, and has good adaptability and practicality.

Focusing on the welded pipe equipment industry and continuously driving technological innovation

ZTZG, as a practitioner who has been dedicated to the welded pipe equipment industry for over 20 years and has been leading industry innovation, will continue to focus on the reform and upgrading of welded pipe equipment and contribute to the high-quality development of the pipe manufacturing machine industry!

Post time: Dec-25-2025