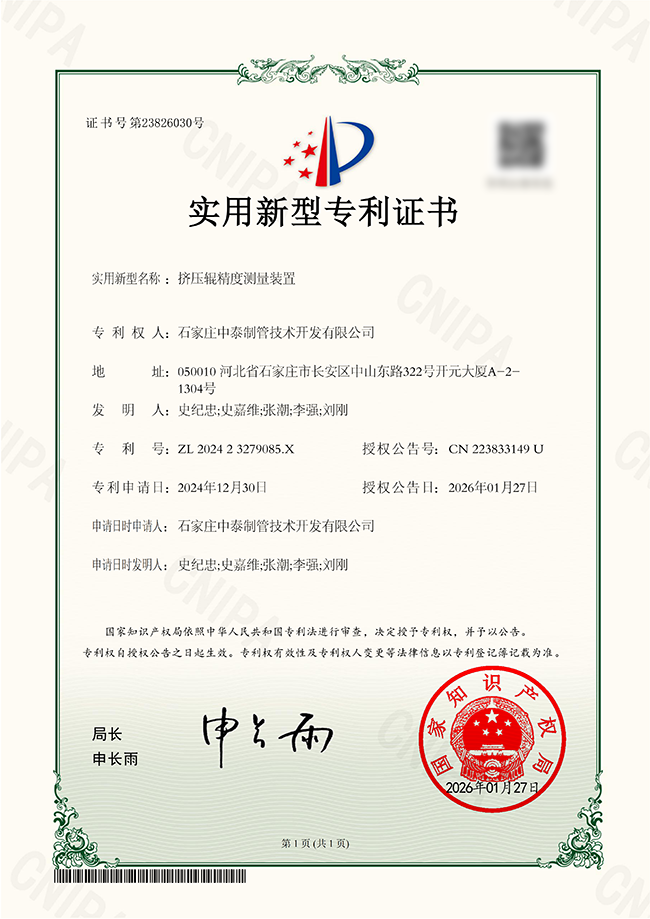

Recently, ZTZG officially obtained a national utility roller patent for a new device specifically designed for measuring the precision of extrusion rollers in welded pipe production lines. Its innovative measurement structure and high-precision data feedback system are expected to solve long-standing industry pain points in the welded pipe manufacturing industry, such as insufficient adjustment precision of extrusion rollers and reliance on manual experience.

Steel pipe forming equipment uses multiple sets of extrusion rollers to sequentially extrude strip steel. The position of the extrusion rollers directly determines the quality of the formed steel pipe. Therefore, high-precision adjustment and repeated positioning of the extrusion rollers directly determine the qualification and quality grade of the products produced by the pipe forming machine.

1. Core Technology: Dual Innovations Construct a Precise Measurement System

The ranging mechanism extends outward through the side wall of the protective housing via a horizontally sliding feedback unit, abutting against the bearing of the extrusion roller to be adjusted, thus measuring the displacement of the extrusion roller.

The matching controller can be electrically connected to the ranging mechanism to record the movement data of the feedback unit.

2. Addressing Industry Pain Points: From “Experience-Based Adjustment” to “Data-Driven Guidance”

In traditional welded pipe production lines, the precision adjustment of extrusion rollers has long relied on the experience and feel of skilled workers. This manual adjustment method is not only inefficient but also inconsistent, directly impacting the quality and stability of welded pipe products.

This patented technology allows operators to make precise adjustments based on data provided by the controller, shifting the adjustment process from experience-based to data-driven.

3. Application Prospects and Significance: Improving Welded Pipe Quality and Driving Intelligent Upgrades

Extrusion rollers are a key component in welded pipe forming. The application of high-precision measuring devices will significantly improve the dimensional accuracy and consistency of welded pipe products, particularly suitable for fields requiring high pipe precision, such as oil and gas pipelines and structural pipes.

Furthermore, the patenting of this extrusion roller precision measuring device represents not only a breakthrough in a single technology but also a significant milestone in the development of welded pipe production equipment towards intelligence and precision.

Next, the ZTZG technical team will continue to promote the intelligentization of the entire welded pipe production process. As this patented technology moves from the laboratory to the production line, my country’s welded pipe equipment manufacturing industry is expected to reach a new level in terms of precision control and quality consistency, thereby enhancing its competitiveness in the global high-end welded pipe equipment market.

Post time: Jan-29-2026