Manufacturer of automated welding pipe equipment without mold change

Specialized in Pipe Production Line

More than 25 years…

Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

We’ve got quite possibly the most state-of-the-art welded pipe production machine, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for China Roll Forming Machine and Pipe Making Machine.

ZTZG’s Round tube making machine with Share-Roller for forming section,

When producing ordinary carbon steel pipes and changing to different production specifications, the forming section mold before welding can be shared, and there is no need to disassemble and replace the mold; only the mold of the sizing section needs to be replaced.

Customers save on mold investment in their pipe welding production lines, improving production efficiency.

It also reduces wear on the welding equipment and reduces labor intensity.

Furthermore, the round pipes produced by this equipment are highly precise, with smoother edges and a more regular appearance.

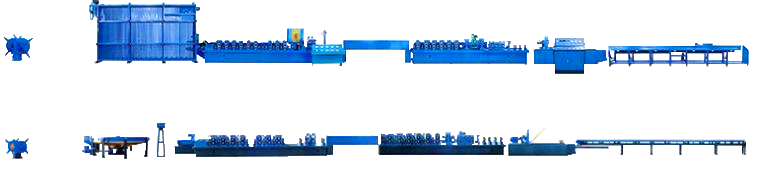

Conventional Round-to-Square ERW Pipe Mill

This production line is a comprehensive complete production line for continuous welding of steel strips into pipes, the strip steel is unrolled by the uncoiler, and then enters the accumulator storage after passing through the shear butt welding machine. The strip steel is extruded by rollers and divided into two parts: break-down section and fine pass section. After high-frequency induction welding and sizing part, output the required length of pipe, cut off by flying saw, and finally stack and pack the steel pipe.

Steel pipe manufacturing process

Scrolling Up→ Uncoiling → Shear and Welding→ Accumulator→ Forming→ HF induction Welding→ External Burr Removing→ Cooling → Sizing→ Flying Saw → Run Out Table →Inspecting→ Packing→ Warehouse

Product Information

Line Component

Material Information

Finished Product

Line Specification

Line Component

| Line Component | Uncoiler Shear & end welder Accumulator Forming & sizing machine H.F welder Flying saw Stacking & packing machine |

| Special | Hydraulic testing machine, intermediate frequency annealing machine, ultrasonic flaw detection machine, etc. |

Material Information

|

Material |

High strength steel, Low carbon steel, GI, etc |

| Strip Steel Width | 90 mm- 400mm |

| Strip Steel Thickness | 1.2 - 4.0mm |

|

Strip Steel Coil |

Inner diameter:Φ 508-610 mm Outer diameter:Φ Max.2000 mm Weight: Max=4.0 T |

Finished Product

| Round Pipe | Φ8-Φ89 mm |

| Thickness | 1.2-4.0 mm |

| Square Tube | 10×10-70×70 mm |

| Thickness | 1.2-4.0 mm |

| Rectangular Tube | 20×40-50×100 mm |

| Thickness | 1.2-4.0 mm |

| Length | 6-12 m |

Line Specification

| Forming Speed | 50-120 m/min (Attn: Max pipe diameter thickness doesn’t correspond with the max speed) |

| Feeding Direction | Left feeding (or right feeding), option by customer |

| Electric Installed Capacity | Approx. 600 kw |

| Production Line Size | 70×6 m |

| Color of Machines | Blue or customized |

| Yearly Out-put | About 40,000 tons |

High Efficiency: Line speed can be up to 120m/min.

Low Wastage: Low unit wastage and low production cost.

High Accuracy: Diameter error is only 0.5/100 of the pipe OD.

Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

New Energy Industry

High-speed Guardrail

Architectural Decoration Industry

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province.

The factory covers an area of 67,000 square meters.

Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new Business Adventure?

Contact Now!

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |