Erw tube mill Quick-Change System

Specialized in Pipe Production Line

More than 23 years...

It is used for rapid roller replacement. Install the roller of the next steel pip e to be produced to the quick-change shaft in advance. When the steel pipe specification needs to be changed, the quick-change mechanism of the rack will push out the shaft with roller specification in use, and the quick-change shaft installed with the new roller can be put into production, so as to achieve the effect of quickly changing the steel pipe specification.

Quick-Change System

The line adopts quick change system for the forming and sizing sections. The backup shafts can be pre-assembled with proper rollers. When switching, uses crown to load the shaft onto the production stands, settle the fixation bolt and connect to the transmission shaft (Transmission shaft is designed as quick-dissemble type which requires no is mount of flange plate screw). The dissemble of shaft utilize hydraulic system for easy operation. This kind of quick-change system has been tested in many scenarios which has proven to have perfectly deal with water back-flow issue and can simultaneously clear the scale cinder and dust while performing.

We're Here To Help You Succeed

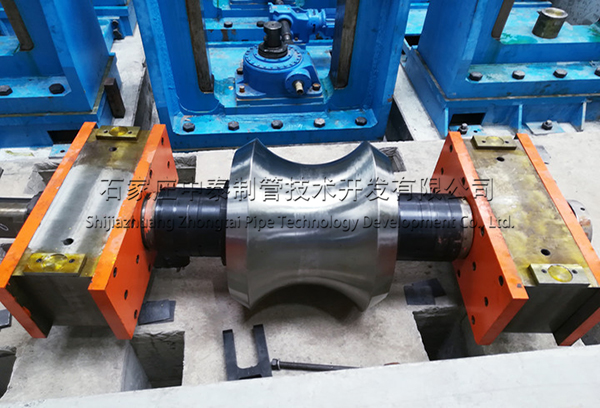

Horizontal Stand Roller Quick-shaft Change System

When changing rollers, pull out the side of the entire shafting unit, lift the shafting unit with the first roller specification from the transport trolley with the crown and put it aside, lift the shafting unit installed with the second roller specification, place it on the transport trolley, and then push the shafting back to the frame. It reduces roller replacement time for the entire mill from ~6 hours to ≤2 hours.

Quick Changing Shaft

When the pipe specification needs to be changed, preload the new specification and the quick-change shaft installed with the new roller can be put into production, so as to achieve the effect of quickly changing the steel pipe specification. If equipped with additional set of shafts, the appr. roller change period is <2 hours.

Product Information

| Steel Pipe Production Line Component | Uncoiler Shear & end welder Accumulator Forming & sizing machine H.F welder Flying saw Stacking & packing machine |

| Equipment Component | Precision forming shafting unit Seam guide roll shafting unit Extrusion rolls shafting unit Roll polishing roll shafting unit Pulling frame shafting unit Sizing straightening machine Shafting unit |

|

Material |

High strength steel, Low carbon steel, GI, etc |

| Strip Steel Width | 320 mm- 2400mm |

| Strip Steel Thickness | Max 22mm |

|

Strip Steel Coil |

Inner diameter:Φ 610-760 mm Outer diameter:Φ 1300-2300 mm Weight: Max=8-30 T |

| Round Pipe | Φ114-Φ720 mm |

| Thickness | 1.2-22.0 mm |

| Square & Rectangular Tube | 80x80mm-600x600mm |

| Thickness | 1.2-22.0 mm |

| Length | 4-16 m |

| Forming Speed | 20-80 m/min (Attn: Max pipe diameter thickness doesn't correspond with the max speed) |

| Feeding Direction | Left feeding (or right feeding), option by customer |

| Electric Installed Capacity | 400kw-2500kw |

| Production Line Size | 78m(length) ×6m (width) -400m(length) ×40m (width) |

| Color of Machines | Blue or customized |

| Yearly Out-put | 8-30 T |

High Automation

One key adjustment of servo motor.

Low Wastage

Low unit wastage and low production cost.

High Accuracy

Diameter error is only 0.5/100 of the pipe OD.

Tube Making Machine Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |