When users purchase welded pipe mill machines, they usually pay more attention to the pipe-making machine's production efficiency. After all, the fixed cost of the enterprise will not change roughly. Producing as many pipes that meet the quality requirements as possible in a limited time means creating more benefits for the enterprise. Therefore, the welded pipe production capacity is one of the criteria for purchasing equipment.

So, what are the factors that affect the production capacity of the equipment? Is the performance of the pipe welding machine high enough to be able to produce as efficiently as expected?

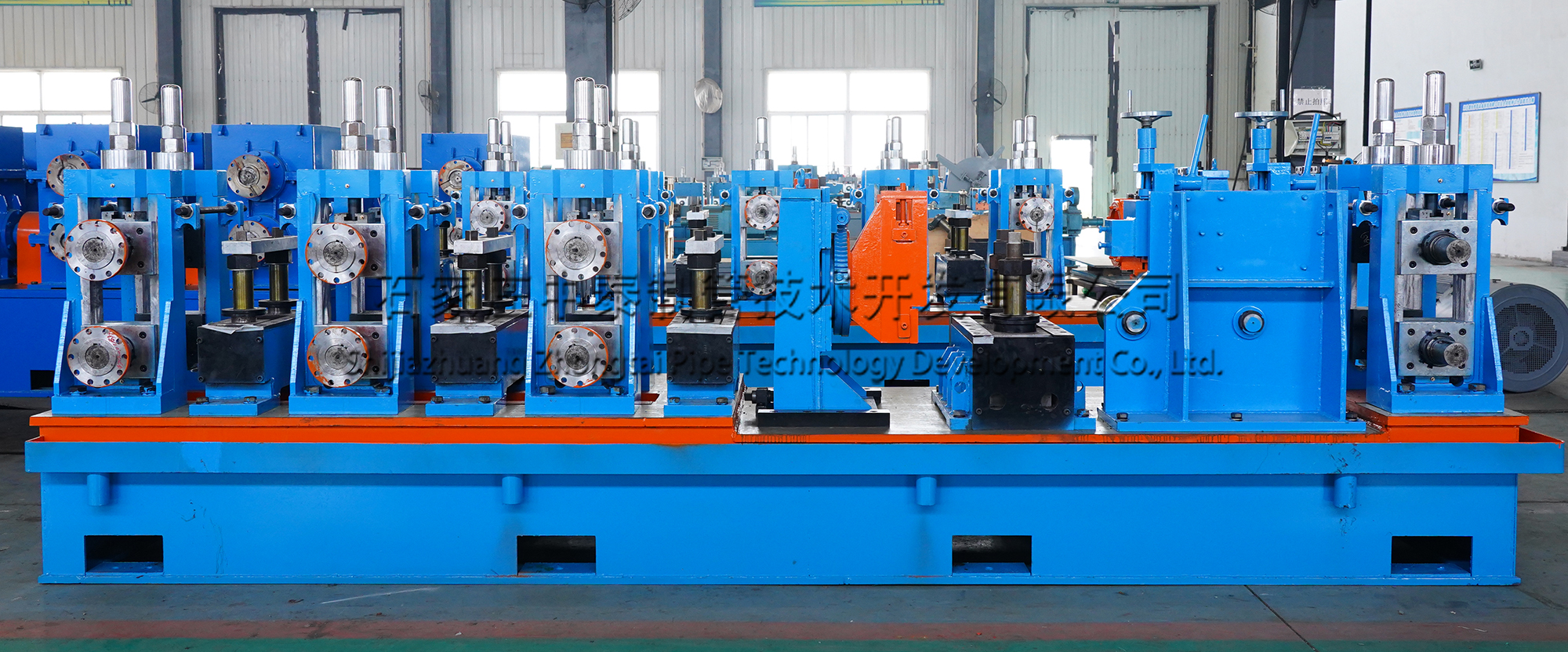

1. The quality of pipe making machine equipment

The quality of the forming section of welded pipe equipment can be considered from two aspects. On the one hand, it is the accuracy of the fixed parts of the machine and the durability of the materials used. The welded pipe is formed in the W forming method, which is a process of reciprocating cycles through the mold. If the horizontal rollers and vertical rollers in the forming section cannot run smoothly, the roundness of the produced pipes will not be high, which will seriously affect the subsequent production process and directly reduce the overall production efficiency.

On the other hand, whether the precision and hardness of the mold have reached the standard for long-term efficient operation. The forming accuracy of the welded pipe equipment developed by ZTZG can be guaranteed within ±0.02mm. The matching mold is made of Cr12MoV material, and after 11 precise processes, it ensures high precision and high standards during use.

2. Welding machine

Welding is the process after forming, and whether the welding machine can perform welding stably is also a key factor that directly affects the entire production efficiency. A high-quality welding machine can keep the entire welding current in a stable state, and it is not easy to cause perforation and other welding problems in the welded pipe due to current fluctuations, and the yield and production process become controllable. The performance and quality of the welding machines provided by ZTZG are recognized by major users in the industry. After optimization by our company, the performance of the production line becomes more suitable for high-speed production requirements.

Post time: Mar-18-2023