OEM/ODM Manufacturer Floor Decking Board Cold Roll Forming Machine

We’ve got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for OEM/ODM Manufacturer Floor Decking Board Cold Roll Forming Machine, We have exported to more than 40 countries and regions, which have gained good reputation from our costumers all over the world.

We’ve got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for China Roll Forming Machine and Roof Panel Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad and create a great future together.

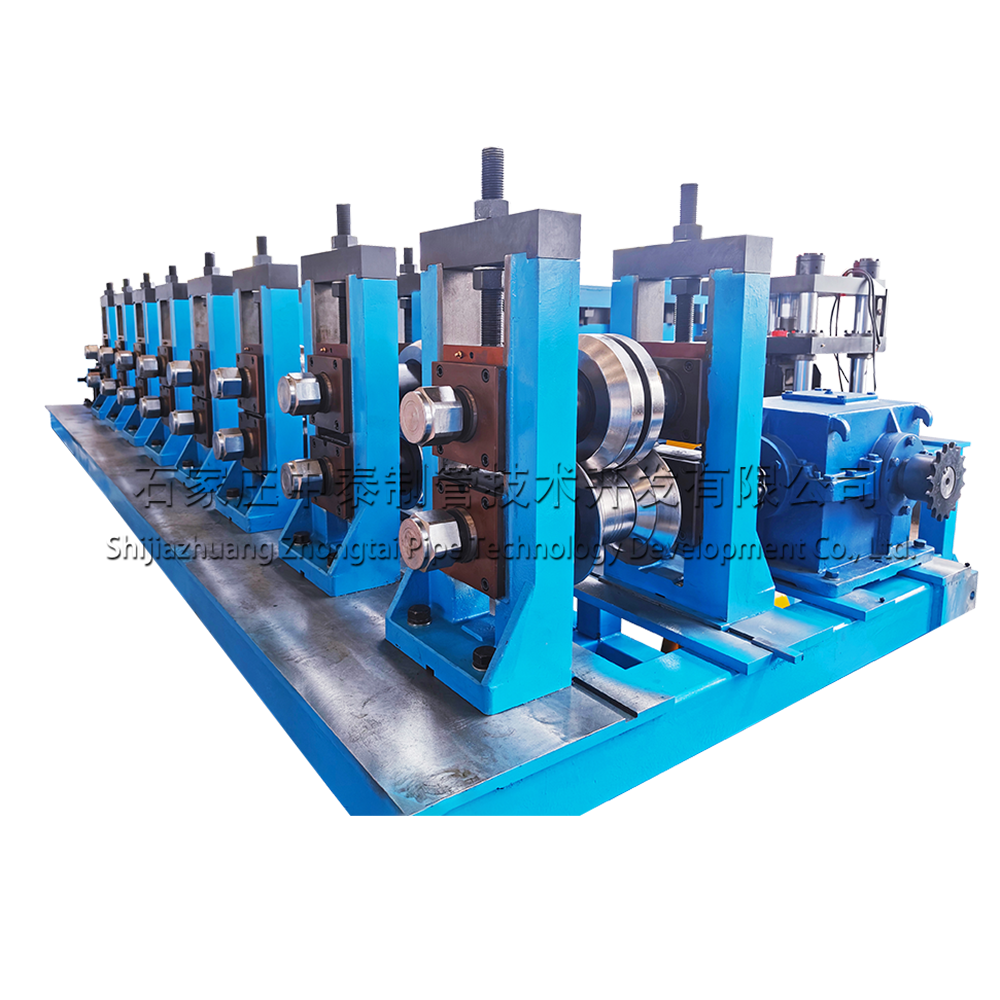

Specialized in Pipe Production Line

More than 23 years…

The Cold Rolled Steel Machine is a high-strength cold forming production line, which is designed for high-strength special plates and can meet the cold forming load. The thickness of finished products is 22mm max, and the material is Q345 (or customized).

Open Section Roll-forming Machinery (U,C,Z,Profile)

It is specialized for cold rolled section steel with wide spread uses for metallurgy, construction, transportation, machinery and vehicle industries. It takes steel strip as raw material, produces cold rolled section steel by cold rolled section forming technology according to relevant request. This kind of technology is advanced and reliable, PROFIBUS technology is also adopted to the control system. All of these ensured highly synchronization accuracy and best product quality. All the indicators and operational costs are controlled at the lowest level, which is greatly rewarded by the producers.

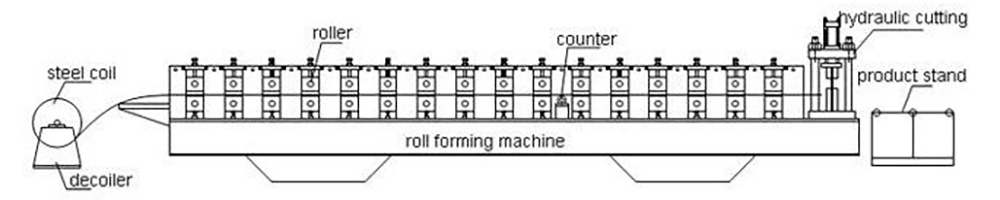

Steel pipe manufacturing process

Uncoiling → Feeding → Forming → Measuring Length → Automatic Cutting → Run Out Table → Inspecting → Packing→ Warehouse

Function and Structure:

The molding of profiles of various specifications, using independent casting frame (tempering treatment).

Universal joint shaft drive: It is easy to adjust and operate.

Roller process design using imported software, computer design.

Product Information

Line Component

Material Information

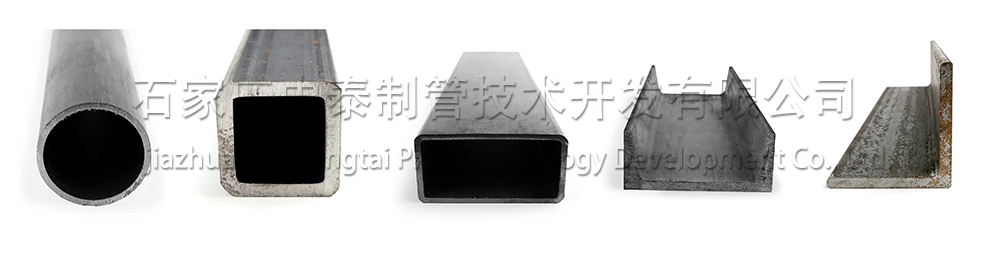

Finished Product

Line Specification

Line Component

| Line Component | Uncoiler Leveler Shearing & Welding Cold Roll Forming Hydraulic Cutting Machine Auto Stacking |

| Special | Computer Control System |

Material Information

|

Material |

High strength steel, Low carbon steel, GI, etc |

| Strip Steel Width | 320mm-2400mm |

| Strip Steel Thickness | 1.2 - 22.0mm |

|

Strip Steel Coil |

Inner diameter:Φ 610mm-760mm Outer diameter:Φ 1300mm-2300mm Weight: Max=8-30 T |

Finished Product

| Shape | C / U / Z Profile, Rectangular Tube |

| Thickness | 1.2-22.0 mm |

| Length | 4-12 m |

Line Specification

| Forming Speed | 0-60 m/min (Attn: Max pipe diameter thickness doesn’t correspond with the max speed) |

| Feeding Direction | Left feeding (or right feeding), option by customer |

| Electric Installed Capacity | 400 kw – 2500 kw |

| Production Line Size | 78m(length) ×6m (width) -400m(length) ×40m (width) |

| Color of Machines | Blue or customized |

| Yearly Out-put | About 30,000-180,000 tons |

High Quality

Low Wastage

High Accuracy

Product Application

We can design and manufacture pipe making machine according to customers’ requirements.

New Energy Industry

High-speed Guardrail

Architectural Decoration Industry

Everything you need to create a steel pipe production line

Our Certificate

Our Company

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!

We’ve got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for OEM/ODM Manufacturer Floor Decking Board Cold Roll Forming Machine, We have exported to more than 40 countries and regions, which have gained good reputation from our costumers all over the world.

OEM/ODM Manufacturer China Roll Forming Machine and Roof Panel Machine, We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade products in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad and create a great future together.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |