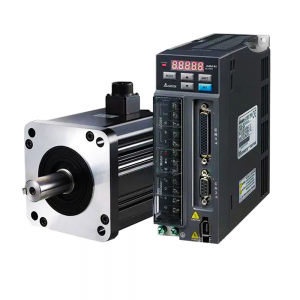

Servo Drive System

The Optimum Motors and Drives System

Servo drive systems are mainly used in packaging machines, handling machines (gripping and handling), wood and ceramic processing machines as well as digital printing machines.

Servo Drive System

The servo system enables simple motion control tasks to be implemented cost-efficiently with the focus being on dynamic motion and processing. ZTZG’s professional engineer supports you when selecting the optimum motors and drives to address your specific load data and motion profiles.

Product Information

|

Power |

SINAMICS S210: 230V 1 AC,0.1kw-0.75kw 400V 3 AC,0.4kw-7kw SIMOTICS S-1FK2: 0.05kw-0.75kw 0.4kw-7kw |

|

Torque Range |

230V 1 AC,0.16 Nm-2.4 Nm 400V 3 AC,1.3 Nm-50 Nm |

|

Security Function |

STO、SS1、SBC、SS21) 、SOS1) 、SLS1) 、SSM1) 、SDI1) 、SLA1) 、SBT1) |

|

Commissioning/configuration |

Web server / Startdrive |

|

EMC Filter |

Integration (1AC 230 V:Class C2 / 3AC 400 V:Class C3) |

|

Standard |

CE、EAC、RCM、KC、cULus |

|

Motor Connection Technology |

One Cable Connection Technology (OCC) with SPEED-CONNECT quick release lock and rotatable compact connector. Permissible cable length: max. 50 m |

|

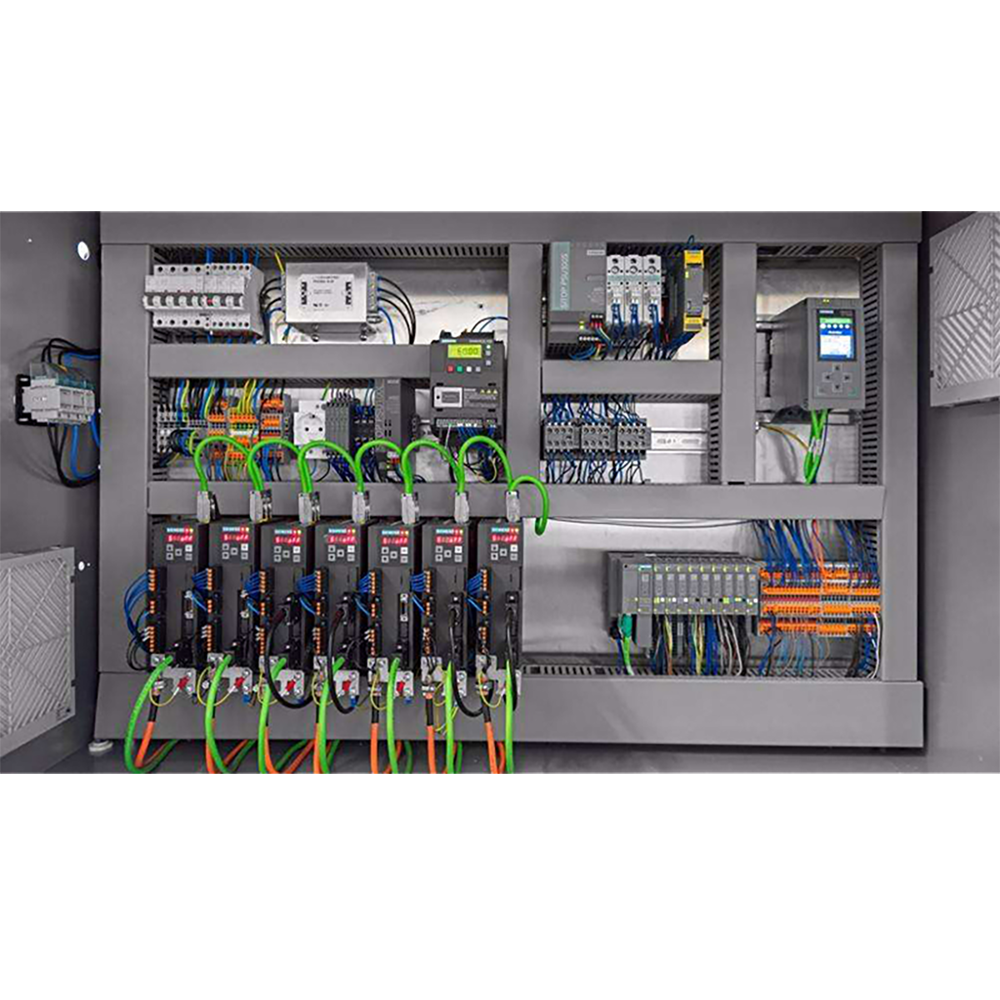

Typical Controller |

SIMATIC S7-1500 / SIMATIC S7-1500 T-CPU / SIMOTION |

|

Motor Type |

•Low moment of inertia version (high dynamic version), motor center height 20 - 63 mm •Medium moment of inertia version (compact), motor center height 30 - 100 mm |

|

Motor Options |

Holding brakes, multiturn and singleturn encoders, feather keys, shaft seals |

Flexible

Security

Excellent

Product Application

Provide customers with smart power control system solutions

Processing

The drive for continuous processes with high speed and torque accuracy

Positioning

The drive for the positioning of individual or multiple coordinated axes

Moving

The drive for simple as well as highly dynamic conveyor systems

Everything you need to create business

Our Certificate

Our Company

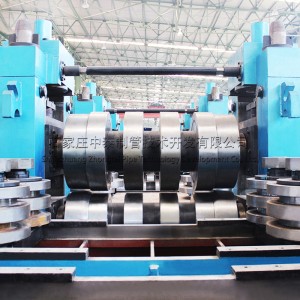

Shijiazhuang Zhongtai Pipe Technology Development Co., Ltd.was established in 2000 locating in Shijiazhuang, the capital city of Hebei Province. The factory covers an area of 67,000 square meters. Our main products consist high frequency straight welded pipe production line, cold roll steel production line, multi-function cold roll steel/welded pipe production line, slitting line production line, stainless steel pipe mill, various pipe mill auxiliary equipment and rollers, etc.

Ready for a new

Business Adventure?

Contact Now!

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |