Good User Reputation for 0.2-2X1250 Hydraulic Slitting Line

To regularly increase the management program by virtue of your rule of “sincerely, good faith and quality are the base of business development”, we extensively absorb the essence of associated solutions internationally, and continuously create new solutions to satisfy the demands of customers for Good User Reputation for 0.2-2X1250 Hydraulic Slitting Line, We encourage you to make get hold of as we’ve been seeking for associates inside our venture. We are sure you are going to locate doing business enterprise with us not only fruitful but also profitable. We are all set to provide you with what you require.

To regularly increase the management program by virtue of your rule of “sincerely, good faith and quality are the base of business development”, we extensively absorb the essence of associated solutions internationally, and continuously create new solutions to satisfy the demands of customers for China Hydraulic Slitting Line System and High Speed Hydraulic Slitting Line System, There are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We’ve got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Description

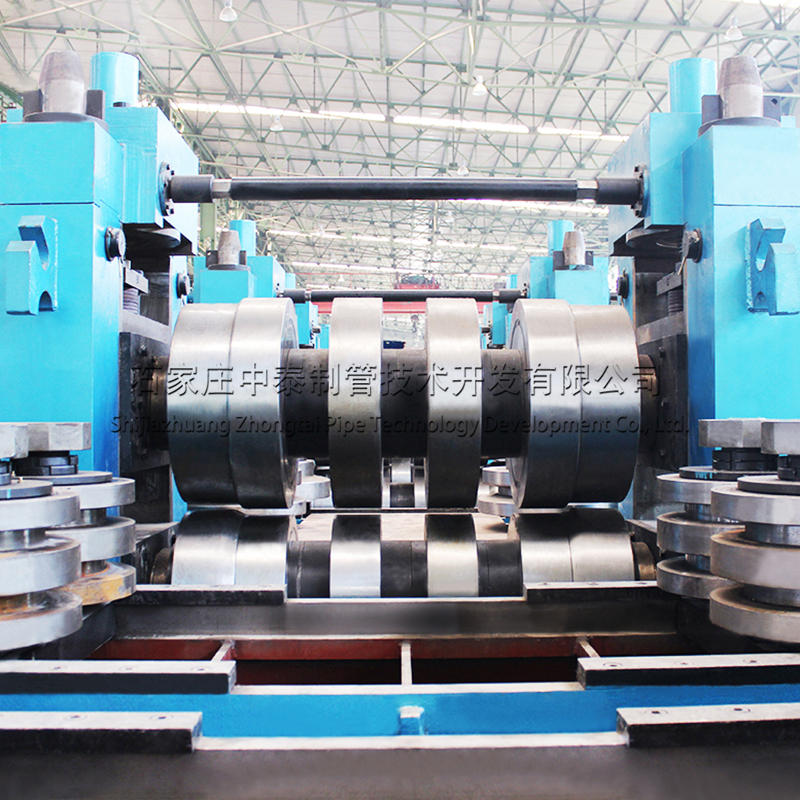

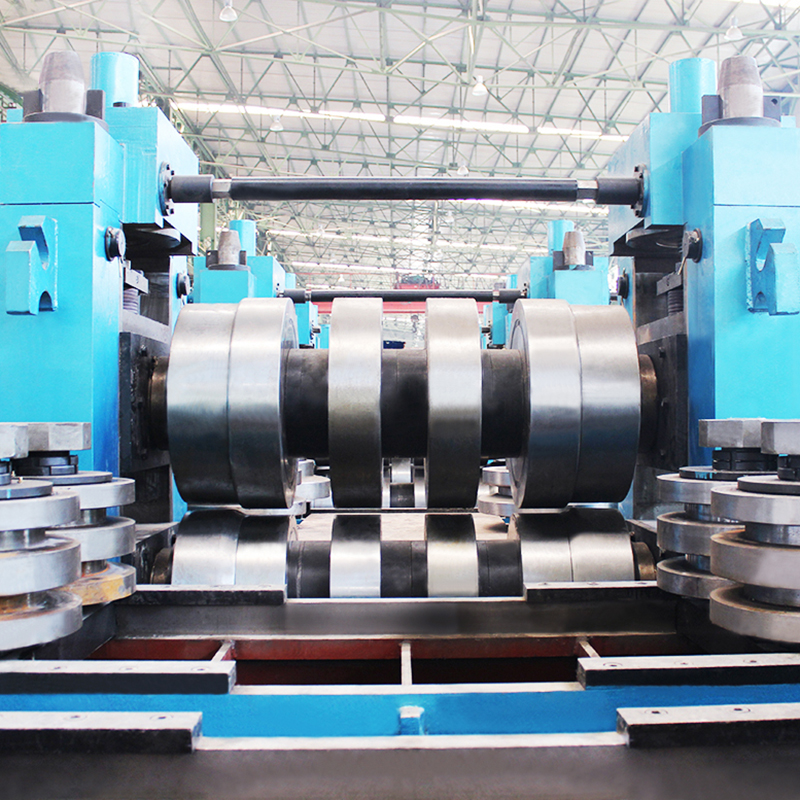

The slitting line PLC control, human-machine interface, according to a high degree of automation, simple operation and reliable. According to the material slitting thickness, there are a thin plate or board slitting machine, a media-thickness plate or board slitting machine, and a thick plate or board slitting machine. According to the metal materials, there are copper strips slitting machine, stainless steel slitting machine, cold or hot rolled plate slitting machine, silicon steel slitting machine.

Technical flow

Coil-loading — Single-mandrel uncoiler — Coil-head-feeding, press & shoveling — Double-roller pinch feeding, three-roller leveling — End-cutting — Hole Accumulator(1) — Strip-aligning — Disc shearing — Scrap reeling — Hole Accumulator(2) — Pre-separator/Tensioner/length-measuring roller — Recoiling/Coils press & separator — Coils-discharging — Hydraulic control — Electric control

Product information

|

Steel coil parameters |

Material | Cold rolled sheets and GI sheets |

| Tensile strength |

Tensile strength δb≤500Mpa, Yield strength δS≤235Mpa |

|

| Steel thickness | 0.2-20mm | |

| Steel width | 400-2200mm | |

| Steel coil weight | 30T | |

| Slit parameter | Max slit quantity | 10 pics (5mm) 7 pics (14mm) |

| Width precision | ±0.05mm | |

| Other parameters | Line speed | 15-60m/min |

| Operator needed | 1 mechanical engineer +2 common workers | |

| Line direction | Customer’s request | |

| Machine color | Customer’s request |

Our Advantage

1) More than 20 years of independent research and development and manufacturing experience. Passed ISO9001 quality system certification and participated in the preparation of a number of industry standards.

2) ZTZG support customization according to international standards in each region, and provide regular technical information and technical training support.

3) There is strict quality control in raw materials, processing accuracy, heat treatment, assembly accuracy, standard parts, etc. The pass rate of equipment delivery is 100%

To regularly increase the management program by virtue of your rule of “sincerely, good faith and quality are the base of business development”, we extensively absorb the essence of associated solutions internationally, and continuously create new solutions to satisfy the demands of customers for Good User Reputation for 0.2-2X1250 Hydraulic Slitting Line, we encourage you to make get hold of as we’ve been seeking for associates inside our venture. We are sure you are going to locate doing business enterprise with us not only fruitful but also profitable. We are all set to provide you with what you require.

Good User Reputation for China Hydraulic Slitting Line System and High-Speed Hydraulic Slitting Line System, there are advanced producing & processing equipment and skilled workers to ensure the merchandise with high quality. We’ve got found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our merchandise is now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |