Leading Manufacturer for Pipe Making Machined53ka Radial Axis CNC Ring Rolling Machine with Good Quality

We get pleasure from a very very good standing between our shoppers for our fantastic product quality, aggressive price as well as very best support for China Ring Grinding Machine and Bearing Rings, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Description

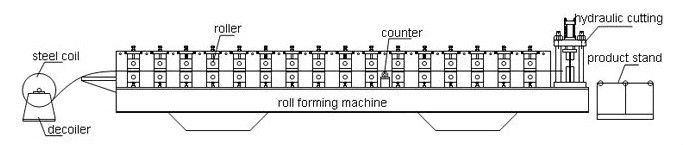

It is specialized for cold rolled section steel with widespread uses for metallurgy, construction, transportation, machinery and vehicle industries. It takes steel strip as raw material, produces cold rolled section steel by cold rolled section forming technology according to relevant request. This kind of technology is advanced and reliable, PROFIBUS technology is also adopted to the control system. All of these ensured highly synchronization accuracy and best product quality. All the indicators and operational costs are controlled at the lowest level, which is greatly rewarded by the producers.

The Cold Rolled Steel Machine is a high-strength cold forming production line, which is designed for high-strength special plates and can meet the cold forming load. The whole line is composed of hydraulic uncoiler - leading head - shovel head - pressing head - leveler - shearing - head, and tail butt welding - cold roll forming - hydraulic cutting - auto stacking, and so on.

Function and Structure:

The molding of profiles of various specifications, using independent casting frame (tempering treatment), base using welding structure, after stress removal treatment. The molding machine adopts an independent archway structure, universal joint shaft drive. Inlet guide device; High-quality carbon steel roller; It is easy to adjust and operate. Roller process design using imported software, computer design.

Product Information

| Product&Yield | Shape | C Profile U Profile Z Profile |

| Length | 4-12m | |

| Production Speed | 0-60m/min | |

| Production capacity | 30,000-180,000ton/year | |

| Consumption | Mill installed capacity | 400kw-2500 KW |

| Line Area | 78m(length) ×6m (width) -400m(length) ×40m (width) | |

| worker | 3-5 人 | |

| Raw Material | Carbon Steel coil | ST37 ST52 |

| Width | 320mm-2400mm | |

| Coil ID | Φ610mm-760mm | |

| Coil OD | Φ1300mm-2300mm | |

| Coil Weight | 8-30ton |

Our Advantage

Broad section steel or profile pipes are widely used in construction work, furniture making, and transportation. Cold rolled broad section production line is specialized for mass-producing such steel. It takes strip steel as raw material and utilizes the cold roll technique to form desired products. All of these ensure high synchronized accuracy and the best product quality. All the indicators and operational costs are controlled at the most economical level.

ZTZG's long history and professional R&D capability in tube mill industry, it is known for its excellent product quality. we can design and manufacture pipe making machine according to customers' requirements and provide regular technical information and technical training support.

We get pleasure from a very very good standing between our shoppers for our fantastic product quality, aggressive price as well as very best support for Leading Manufacturer for Pipe Making Machined53ka Radial Axis CNC Ring Rolling Machine with Good Quality, we sincerely welcome abroad buyers to consult for that long-term cooperation plus the mutual advancement.

Leading Manufacturer for China Ring Grinding Machine and Bearing Rings, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

|

ERW TUBE MILL LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working spead m/min |

|

|

ERW20 |

Ф8-Ф20 |

6x6-15×15 |

0.3-1.5 |

120 |

Read More |

|

ERW32 |

Ф10-Ф32 |

10×10-25×25 |

0.5-2.0 |

120 |

|

|

ERW50 |

Ф20-Ф50 |

15×15-40×40 |

0.8-3.0 |

120 |

|

|

ERW76 |

Ф32-Ф76 |

25×25-60×60 |

1.2-4.0 |

120 |

|

|

ERW89 |

Ф42-Ф89 |

35×35-70×70 |

1.5-4.5 |

110 |

|

|

ERW114 |

Ф48-Ф114 |

40×40-90×90 |

1.5-4.5 |

65 |

|

|

ERW140 |

Ф60-Ф140 |

50×50-110×110 |

2.0-5.0 |

60 |

|

|

ERW165 |

Ф76-Ф165 |

60×60-130×130 |

2.0-6.0 |

50 |

|

|

ERW219 |

Ф89-Ф219 |

70×70-170×170 |

2.0-8.0 |

50 |

|

|

ERW273 |

Ф114-Ф273 |

90×90-210×210 |

3.0-10.0 |

45 |

|

|

ERW325 |

Ф140-Ф325 |

110×110-250×250 |

4.0-12.7 |

40 |

|

|

ERW377 |

Ф165-Ф377 |

130×130-280×280 |

4.0-14.0 |

35 |

|

|

ERW406 |

Ф219-Ф406 |

170×170-330×330 |

6.0-16.0 |

30 |

|

|

ERW508 |

Ф273-Ф508 |

210×210-400×400 |

6.0-18.0 |

25 |

Read More |

|

ERW660 |

Ф325-Ф660 |

250×250-500×500 |

6.0-20.0 |

20 |

Read More |

|

ERW720 |

Ф355-Ф720 |

300×300-600×600 |

6.0-22.0 |

20 |

Read More |

|

STAINLESS STEEL PIPE PRODUCTION LINE |

|||||

|

Model |

Round pipe mm |

Square pipe mm |

Thickness mm |

Working speed m/min |

|

|

SS25 |

Ф6-Ф25 |

5×5-20×20 |

0.2-0.8 |

10 |

Read More |

|

SS32 |

Ф6-Ф32 |

5×5-25×25 |

0.2-1.0 |

10 |

Read More |

|

SS51 |

Ф9-Ф51 |

7×7-40×40 |

0.2-1.5 |

10 |

Read More |

|

SS64 |

Ф12-Ф64 |

10×10-50×50 |

0.3-2.0 |

10 |

Read More |

|

SS76 |

Ф25-Ф76 |

20×20-60×60 |

0.3-2.0 |

10 |

Read More |

|

SS114 |

Ф38-Ф114 |

30×30-90×90 |

0.4-2.5 |

10 |

Read More |

|

SS168 |

Ф76-Ф168 |

60×60-130×130 |

1.0-3.5 |

10 |

Read More |

|

SS219 |

Ф114-Ф219 |

90×90-170×170 |

1.0-4.0 |

10 |

Read More |

|

SS325 |

Ф219-Ф325 |

170×170-250×250 |

2.0-8.0 |

3 |

Read More |

|

SS426 |

Ф219-Ф426 |

170×170-330×330 |

3.0-10.0 |

3 |

Read More |

|

SS508 |

Ф273-Ф508 |

210×210-400×400 |

4.0-12.0 |

3 |

Read More |

|

SS862 |

Ф508-Ф862 |

400×400-600×600 |

6.0-16.0 |

2 |

Read More |